Kunming TOS Machine Tool Co., Ltd. is a Sino-foreign joint venture established in 2005 through a joint investment between General Technology Group Kunming Machine Tool Co., Ltd. and Czech TOS VARNSDORF A.S. This collaboration aims to introduce world-leading European machine tool manufacturing technologies to China while providing high-quality equipment and after-sales services to domestic and international clients.

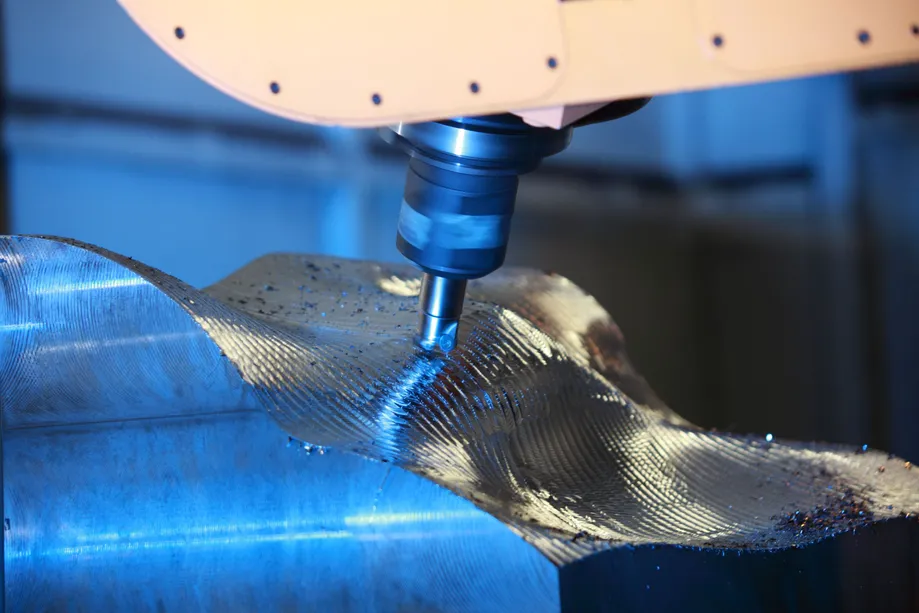

The company integrates R&D, production, and sales of machine tools. Core components like spindle boxes are fully imported from the Czech Republic. Its product portfolio encompasses three major series:

1.Heavy-duty horizontal machining centers (TOSPRES series)

2.Planer-type milling and boring machines (WHN/WHR series)

3.Floor-type milling and boring machines (WRD series)

Additionally, it holds authorization to sell all models of original TOS VARNSDORF equipment in the Chinese market. Customized rotary tables and accessories are also available per client requirements.

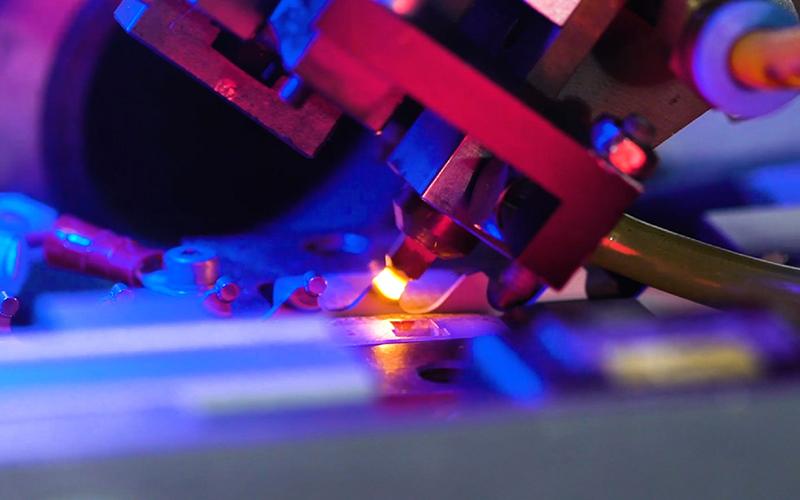

Serving diverse industrial sectors including:

1.Transportation equipment

2.Mechanical manufacturing

3.Shipbuilding

4.Construction machinery

5.Chemical engineering

6.Mold production

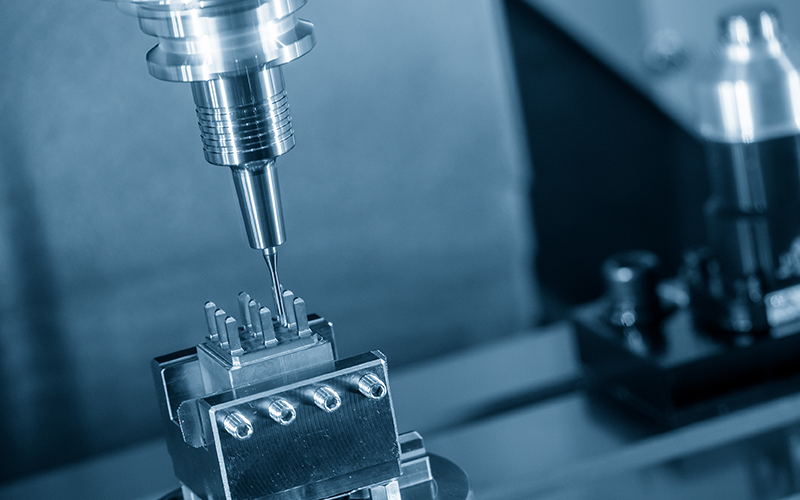

The company has earned an excellent reputation through its aerospace-grade precision and reliability. Notably, its products have passed ISO9001 certification and feature advanced European manufacturing techniques inherited from TOS VARNSDORF's century-old expertise.

With an international management platform and customer-centric philosophy, Kunming TOS remains committed to technological innovation and value creation for clients, striving to propel the development of China's high-end CNC machine tool industry.

Dian Public Security Registration No. 53080202000194

Dian Public Security Registration No. 53080202000194